UAV Design Process

PURA UAV Team | Publication Date: May 2025

The design process of an Unmanned Aerial Vehicle (UAV) requires careful planning, engineering precision, and innovative thinking. In this article, we explore our team's approach to designing competition-ready UAVs using Solidworks, from initial concept to flight testing. We'll cover the entire workflow including 3D modeling, carbon fiber component selection, and our specialized folding arm mechanism.Solidworks: Our Engineering Foundation

Solidworks is widely recognized as a premier engineering design application used across various industries. Our team utilizes this powerful software for creating detailed UAV designs for competitions. After establishing our project requirements, we began by generating innovative UAV design concepts that would fulfill our mission parameters efficiently.

Chassis Design Approach

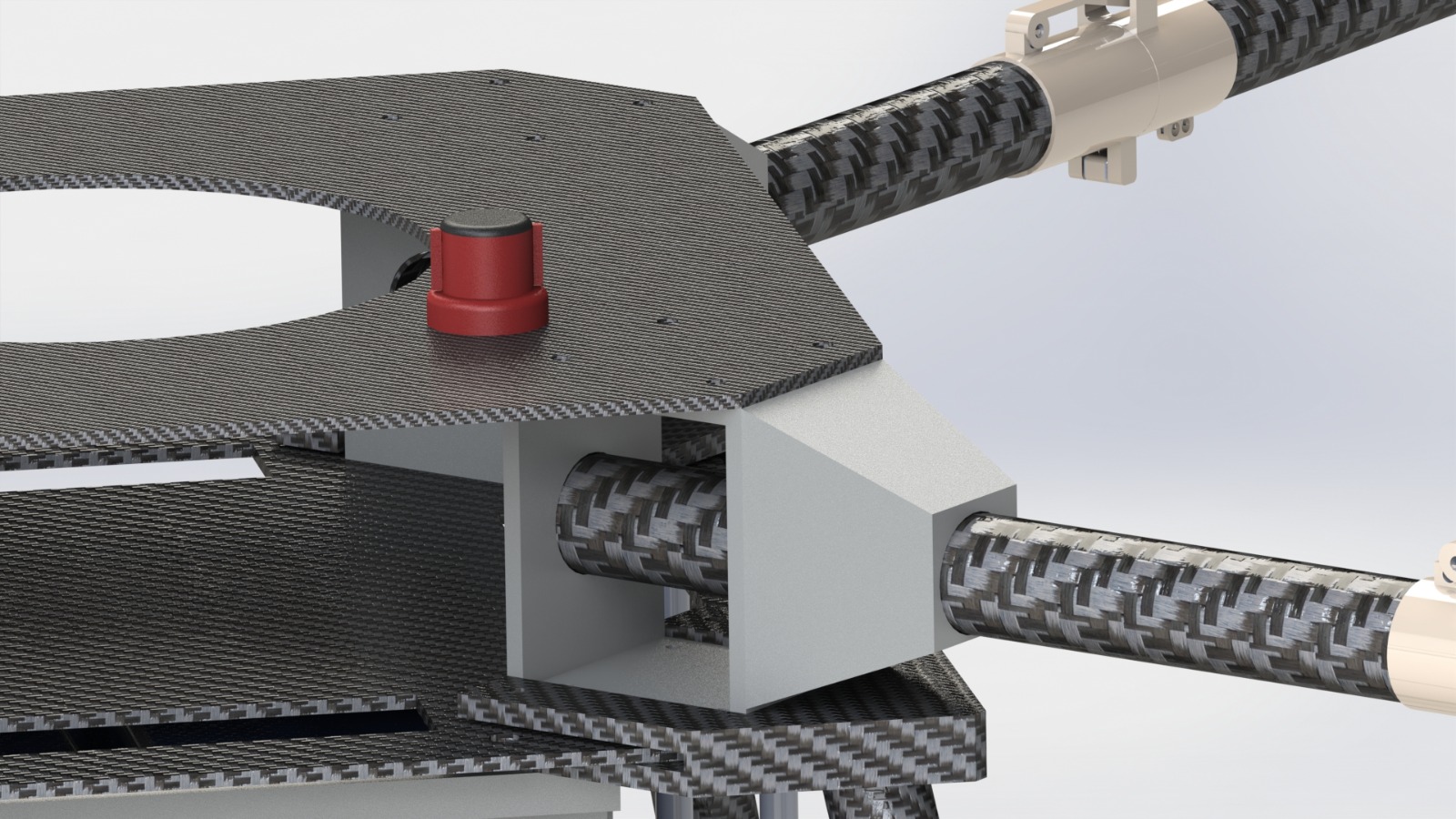

Our design process started with creating three body plates that would provide sufficient area for all required components. We carefully positioned each component to optimize weight distribution and maximize stability during flight. Precise hole placements were calculated to ensure proper alignment of all elements. The dimensions of carbon fiber tubes were meticulously determined and incorporated into the design.

.jpeg)

.jpeg)

.jpeg)

Critical Component Design

All support components for the UAV were designed in Solidworks, including:

- Frame-arm connectors

- Motor mounts

- Landing gear components

- Battery housing

- Mission mechanism

- Additional support structures

After completing the digital designs, we performed virtual assembly in Solidworks to verify proper fit and function before moving to physical manufacturing.

.jpeg)

.jpeg)

From Digital to Physical: Manufacturing Process

With completed designs, we moved to the manufacturing phase. The frame-arm connectors, motor mounts, landing gear components, and support structures were 3D printed to begin physical assembly. Carbon fiber plates were ordered and precision-cut to the specified dimensions from our CAD designs.

Due to competition space constraints, we incorporated an innovative arm folding mechanism into our design. Weight optimization was a critical factor throughout the process, influencing our choices of print density, infill patterns, and overall component dimensions.

Mission-Specific Design Elements

The competition required our UAV to drop objects at specific locations, so we designed a specialized release mechanism positioned on the UAV's underside. This placement prevents interference with any obstacles during the release operation while maintaining the aircraft's stability.

After completing the assembly of all components, we conducted thorough testing for:

- Structural integrity

- Flexural resistance

- Component durability

- Overall system functionality

Only after passing all these rigorous tests was the UAV declared flight-ready.

Final assembly and testing of our competition UAV